Why the selection of bearing clearance determines service life and smooth running

Bearing clearance is one of the most important – and at the same time one of the most frequently misunderstood – parameters in bearing technology. Whether deep groove ball bearings, cylindrical roller bearings or spindle bearings: radial or axial clearance directly affects how a bearing runs, how it heats up and how long it lasts. Selecting the correct clearance determines reliability, precision and the performance of the entire machine assembly.

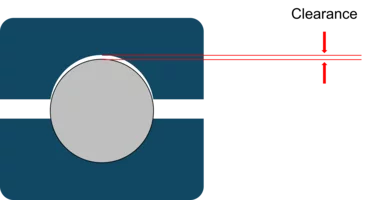

What does bearing clearance actually mean?

Bearing clearance describes the internal free movement between the rolling elements and the raceways. It exists in two forms:

- Radial clearance

- Axial clearance

Depending on the bearing type, a bearing is supplied with standardized clearance (e.g. CN) or increased clearance (e.g. C3). Even deviations in the micrometer range significantly change the operating behaviour.

C3 is not “better” – it is simply different

In practice, there is a persistent assumption that a C3 bearing is inherently superior or allows higher load ratings. This interpretation is incorrect. C3 is not a quality grade and does not improve the bearing by itself.

C3 simply means that the bearing has a larger internal radial clearance than a bearing with standard clearance (CN).

This increased clearance is a pure compensation factor and is required when, during operation:

- high temperatures occur

- high rotational speeds are used

- tight fits reduce ring dimensions

- thermal expansion must be compensated

In these cases, a bearing with standard clearance (CN) would run too tight, and the operating clearance would approach zero. C3 ensures that, despite heat and interference fits, stable operating clearance is maintained.

If C3 is selected without technical necessity, the opposite effect occurs:

Excessive internal clearance leads to higher noise, unstable running behaviour, increased vibration and accelerated wear.

The objective is therefore not to choose “more” clearance, but the correct clearance – matched to temperature, fits and operating conditions.

Too little clearance is equally harmful

Insufficient bearing clearance can be just as problematic. If heat or press fits drive the clearance toward zero, this results in:

- internal stress

- increased friction torque

- higher temperature

- premature wear

The optimum is therefore not the smallest or largest clearance, but the correct clearance for the actual operating conditions.

Why clearance is a system parameter

Clearance selection must never be made in isolation. What matters is the complete system of:

- bearing type

- shaft and housing fits

- temperature distribution

- speed, load and duty cycle

- lubrication

- installation environment

- materials and thermal expansion

At SKA®, these factors are considered together. The goal is to achieve the intended operating clearance – not simply the catalogue clearance.

Practice: calculation + experience

At SKA®, clearance selection is based on a combination of calculation, measurement data and many years of application experience. Many applications cannot be represented by tables alone. Temperature profiles, housing geometries, fits, lubricants and load changes vary from customer to customer and from application to application. By systematically analysing real operating conditions, a complete picture is created that sensibly complements theory.

Typical procedure:

- Analyse the application

- Determine load and temperature profile

- Calculate the influence of fits

- Select optimal clearance

- Define lubrication and preload

The result is a clearance that works not only in theory but remains stable under real operating conditions. By considering temperature gradients, mounting fits and dynamic loads, an operating clearance is achieved that prevents both internal stress and unnecessary vibration. This leads to a robust and reliable solution that supports bearing life and machine performance.

Conclusion

Selecting the correct bearing clearance is one of the decisive factors for service life, smooth running and operational reliability.

Proper clearance reduces temperature, minimizes friction and prevents damage such as brinelling, misalignment or wear.

With SKA®, users benefit from engineering support, experience and clear recommendations.

→ Learn more at www.ska.swiss and www.ska.swiss/en/products-solutions/product-details/bearing-clearance