Damage analysis and root cause investigation

We analyse causes, not just symptoms.

In the event of damage, our technical laboratory is available for thorough and systematic analyses. The aim is to identify the actual cause of a failure, prevent recurring faults and highlight specific areas for improvement.

Our investigations are based on established evaluation procedures and decades of experience in roller bearing design, assembly and service life assessment. Every analysis is transparent, reproducible and fully documented, from the initial findings to the technical recommendation.

Typical damage patterns

We document and classify all common types of damage, including:

- Running-in marks and surface wear

- Overheating or lubricant failure

- Corrosion, brinelling, material removal

- Assembly errors, misalignment or incorrect bearing clearance

- Foreign particle or sealing problems

- Stress corrosion, cracks or dynamic fractures

Visual inspection and microscopic image of the raceways and rolling elements

Identification of typical damage patterns (e.g. pitting, chatter marks, cracks)

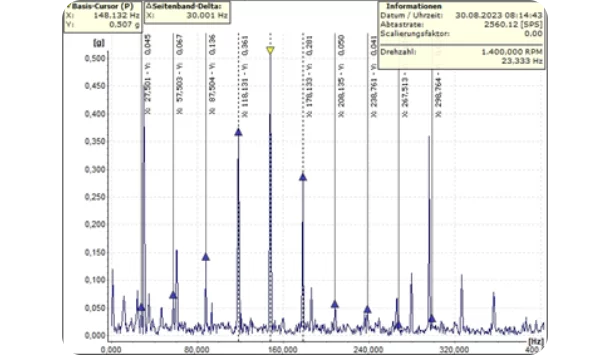

Evaluation of operating parameters (temperature, lubrication, preload, speed, load)

Evaluation of operating parameters (temperature, lubrication, preload, speed, load)

Preparation of a technical analysis report with photo documentation, assessment of causes and recommendations for preventive action