Centre for Development and Quality Validation.

The testing laboratory at the headquarters in Stachen (Switzerland) forms the heart of SKA's quality assurance system. Here, initial samples, reference stock and series approvals are tested, documented and analyzed in accordance with defined DIN and SKA standards that exceed industry requirements. This creates a reliable basis for reproducible quality across all production sites.

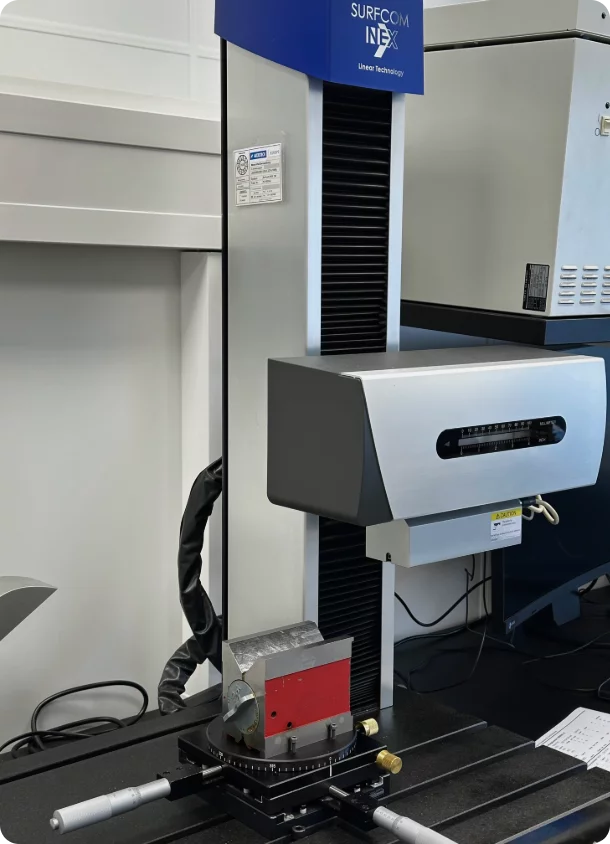

Tests at the highest technical level

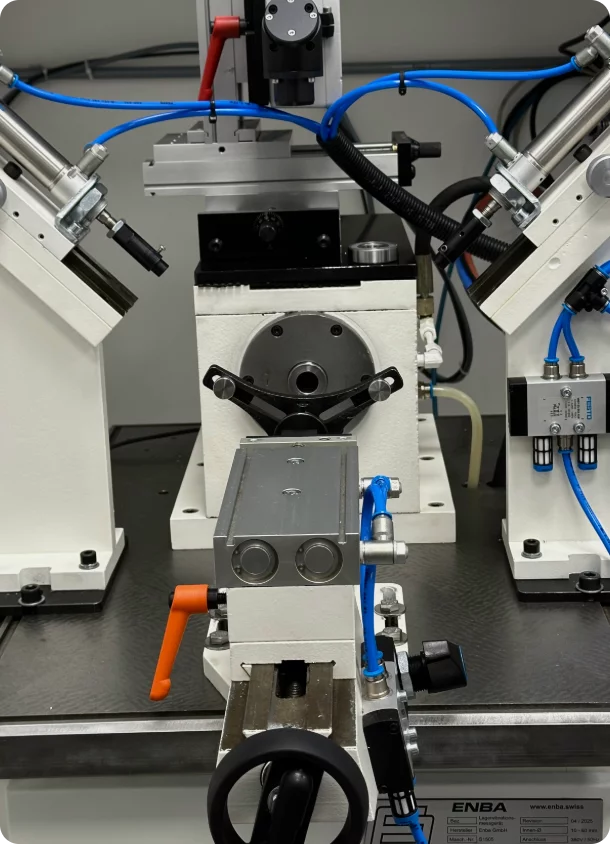

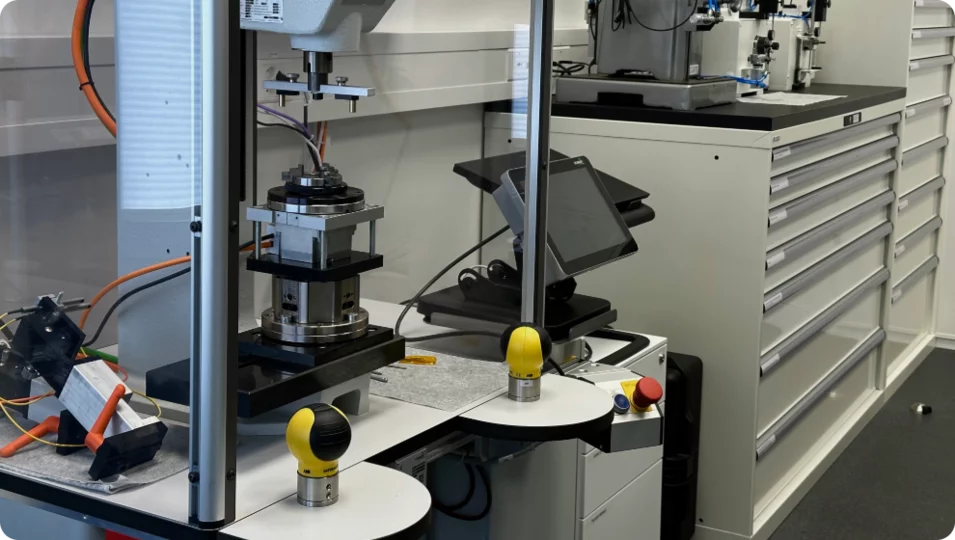

The Swiss laboratory covers a wide range of mechanical, geometric and acoustic tests that enable a complete assessment of bearing quality.

At the same time, it acts as a development and validation centre for new specifications, test matrices and customer-specific acceptance criteria.

This is where the standards for our production plants are defined.

An overview of our testing methods

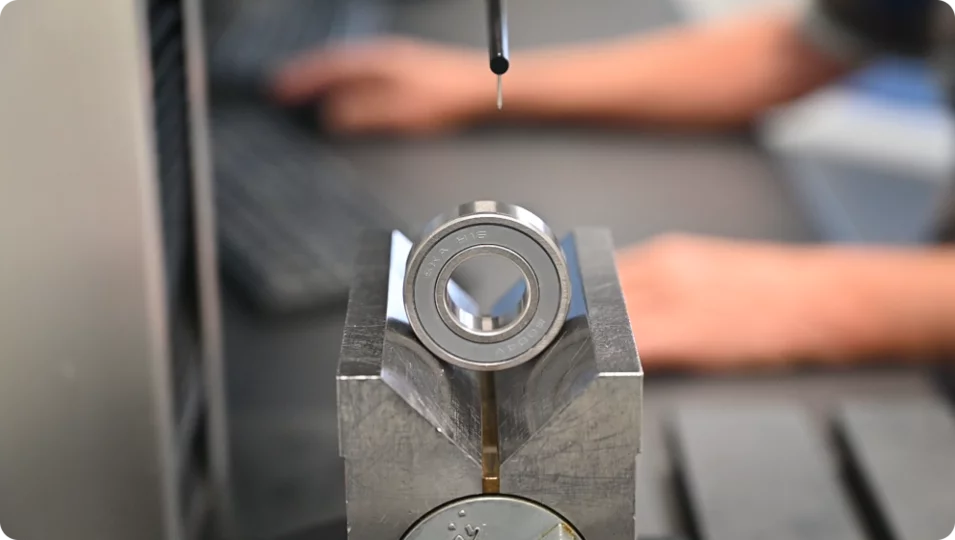

Recording of all relevant dimension and geometry values in accordance with DIN 620 – the basis for precision fit and functional reliability.

Testing of bearing running properties to ensure synchronization, precision and minimal vibration.

Measurement in accordance with DIN EN 15242 for assessing noise development and friction behaviour under operating conditions.

Assessment of roughness, structure and texture in accordance with DIN EN ISO 21920 – crucial for lubricating film stability and service life.

Checking bearing force distribution and start-up behaviour to optimise energy efficiency and assembly precision.

Visual inspection of seals, coatings and markings in accordance with SKA's internal testing standards.

Application of special test procedures in accordance with customer specifications or drawing requirements, including prototype tests and comparative measurements.

Documentation, traceability and transparency

All measurement results are recorded digitally, archived in a traceable manner and systematically evaluated.

This enables Labor Schweiz to ensure complete traceability for every batch tested – CE-compliant, traceable and approved in accordance with DIN and SKA guidelines.

The combination of measurement technology, experience and documentation makes Stachen a centre of excellence for precision and technical reliability.

Impressions

where precision moves