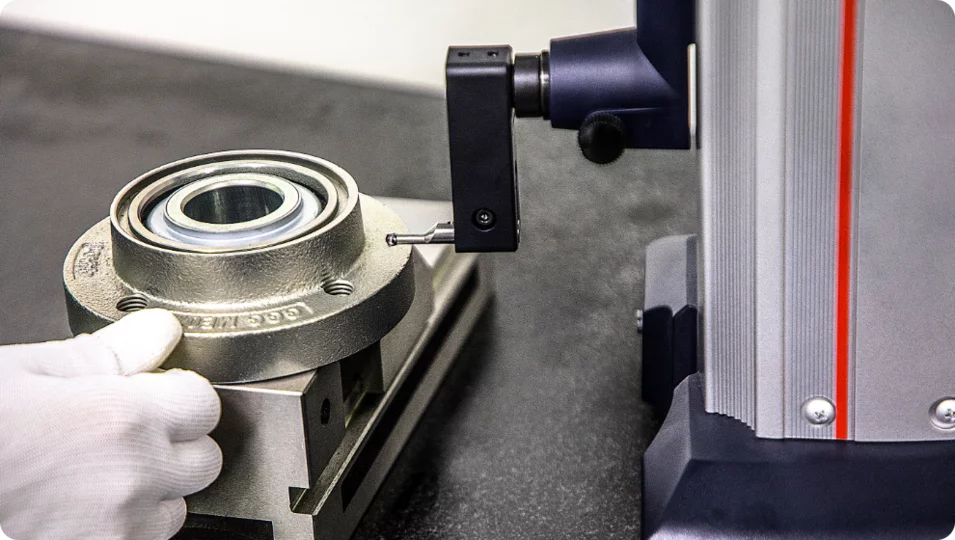

Global quality testing in the production environment

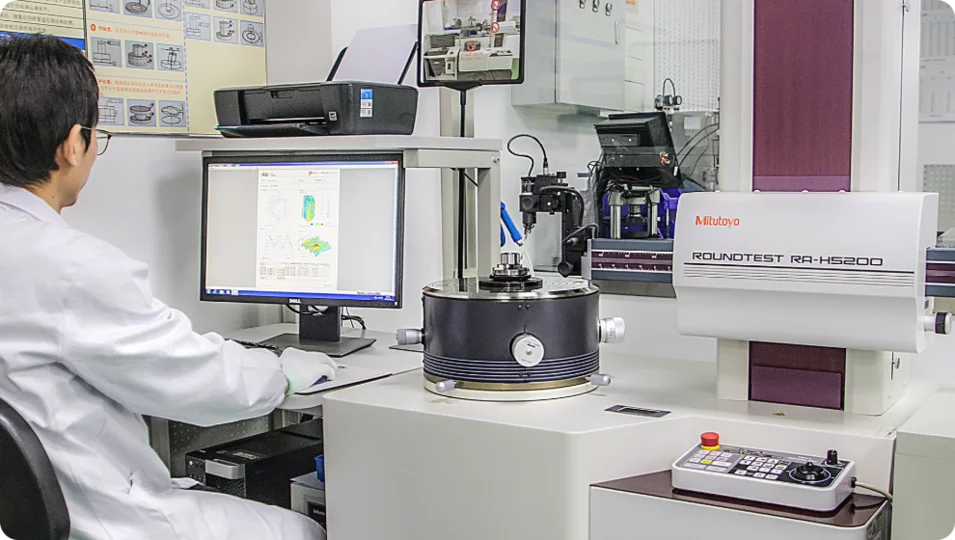

The laboratory in Shanghai is the operational link between production and quality approval. Here, each batch is tested in accordance with DIN and SKA standards before shipment, documented and digitally transmitted to Switzerland. This creates a globally coordinated testing system that ensures consistency and transparency across all locations.

Series testing and AQL approvals

Quality control in Shanghai follows a clearly defined, AQL-based testing concept:

- AQL 1.0 for industrial products

- AQL 0.65 for high-precision applications

- Customer-specific values in accordance with QSV specifications

Core tests include dimensional and geometric checks, surface and running behaviour tests, noise measurements and initial sample tests in accordance with DIN standards.

On request, PPAP processes can also be carried out in accordance with customer requirements – including process diagrams, test methods and series approvals.

Traceability and process reliability

All test data and results are recorded centrally, transmitted digitally and compared with the laboratory in Switzerland.

This two-stage system – series testing in Shanghai and reference validation in Stachen – ensures consistent quality for every delivery, regardless of the factory or production period.

The close integration of the individual steps creates a closed quality system that covers the entire product life cycle: from manufacturing and testing to documented approval.

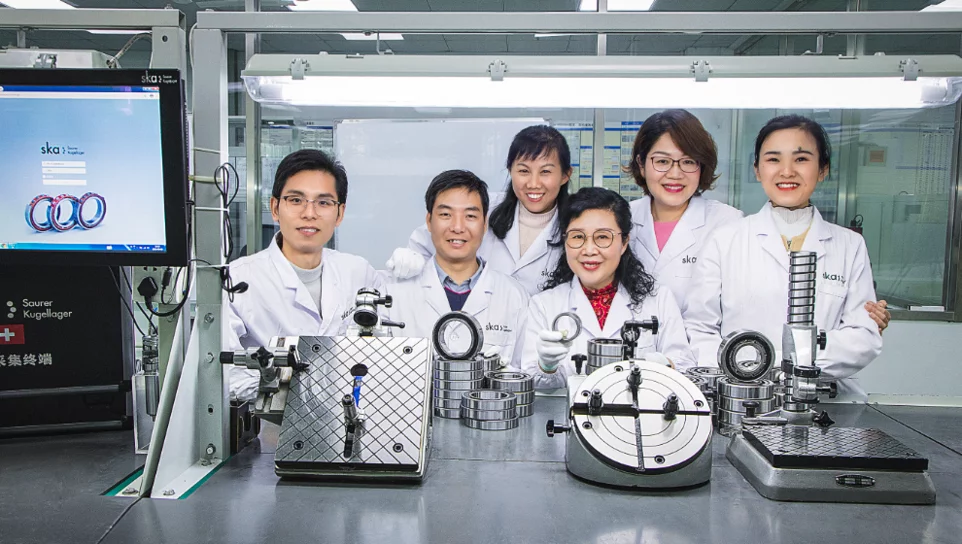

Emotional with a global perspective – our SKA QS team in Shanghai

Our silent heroes in Shanghai work every day with the same precision, dedication and sense of quality that have defined SKA® for decades.

Their work ensures a reliable global supply of flawless products – inspected, documented and produced with pride.

Impressions

where precision moves