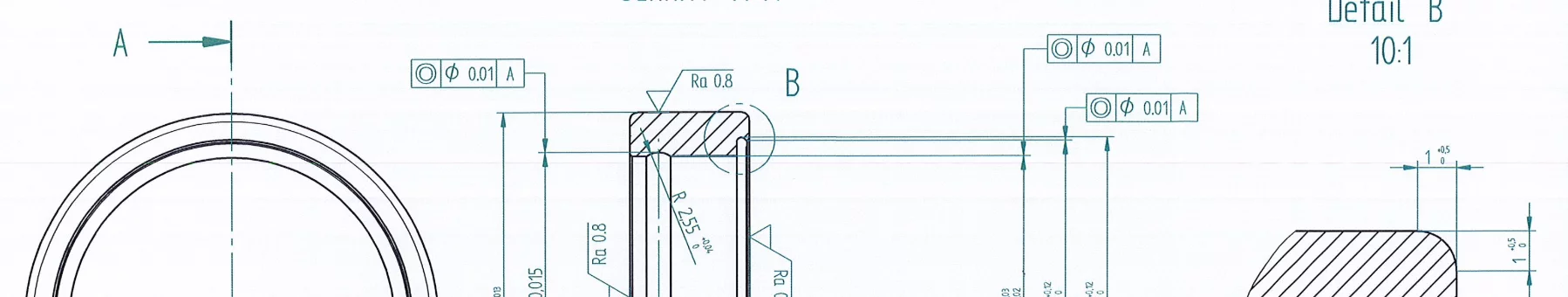

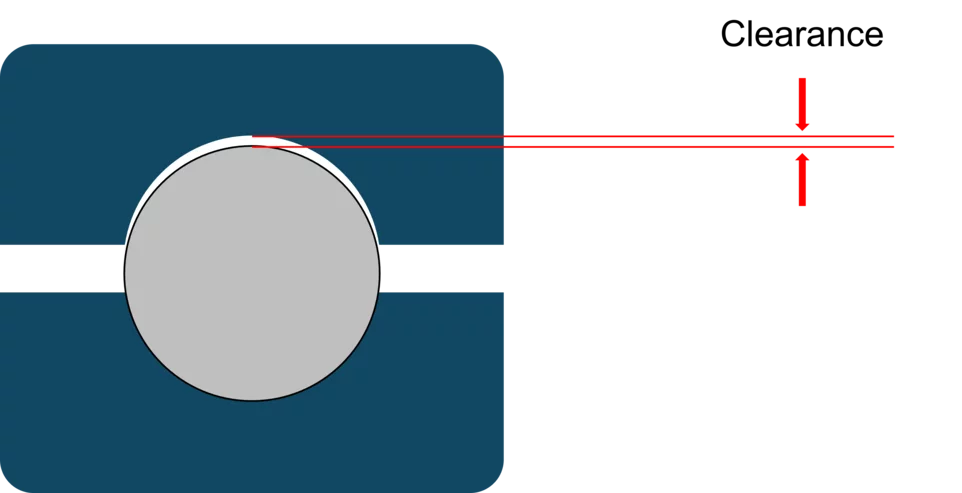

Bearing clearance during operation

The bearing clearance describes the radial or axial play between the raceways of a bearing when installed. It directly influences friction, temperature behaviour, running accuracy and service life.

The effective bearing clearance results from the selected bearing clearance class, the installation fits of the shaft and housing, and the temperature differences during operation. If the bearing clearance is too small, the friction torque and heating increase. If it is too large, vibrations, uneven load distribution and increased wear occur.

Bearing clearance classes and selection

For standard applications, the CN (C0) bearing clearance class is generally used, which offers a balanced compromise between smooth running and stability.For higher loads or temperature influences, extended classes such as C3 or C4 are available, while C2 is used for particularly backlash-free precision bearings.

For small and miniature bearings, classes MC1 to MC6 are also used to enable finer gradations in the μm range – MC3 is preset as standard.

Influence of installation and temperature

During installation, the bearing clearance changes due to fitting tensions between the inner and outer ring. A tight shaft fit reduces the radial bearing clearance, while a tight housing fit can increase it.

Temperature differences between the inner and outer ring also affect the bearing clearance, especially at high speeds or with increased friction. To ensure optimum function, the effective operating bearing clearance should be within the specified tolerances.

Hans Saurer Kugellager AG supports its customers in selecting the appropriate bearing clearance class, taking into account load, speed, ambient temperature and installation conditions.

where precision moves.