Precision begins in the details.

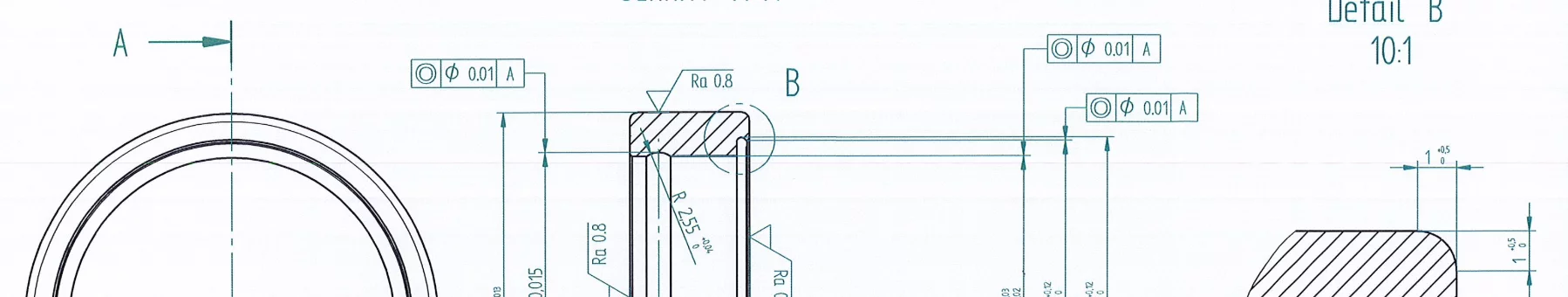

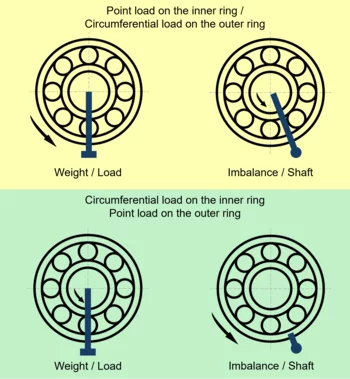

In order for a bearing to perform at its best, it must be properly secured to the shaft and in the housing. The selection of the appropriate fit must always be adapted to the load situation and the running behaviour, as this is crucial for the operational safety and service life of the bearing.

Fits as the basis for precise bearings

The selection of suitable shaft and housing tolerances is a decisive factor for the function and service life of a bearing.

It influences not only smooth running, but also bearing clearance, heat generation and operational reliability. Depending on the type of load, rotational movement and installation situation, the fit must be selected so that it allows a secure fit without creating excessive preload or loosening.

Influencing factors and selection criteria

The installation tolerances depend on several parameters, including load direction, rotational speed, temperature behaviour and material pairing.

Tight fits are recommended for rotating inner rings to prevent relative movement. A looser fit can be selected for stationary inner rings. The materials used for the shaft and housing also influence the selection, especially in the case of aluminium or hollow shafts, whose expansion behaviour differs from that of steel.

The international standards ISO 286, ISO 492 and ISO 199 apply to dimensioning. In addition, SKA®'s own empirical values from laboratory and field applications are taken into account. The aim is to ensure the required bearing clearance after assembly under operating conditions.

where precision moves.