Tolerance of bearings

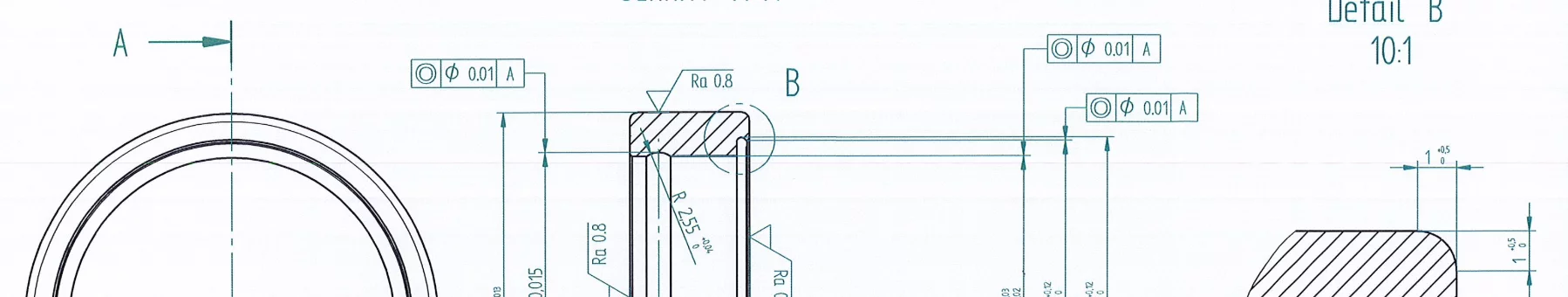

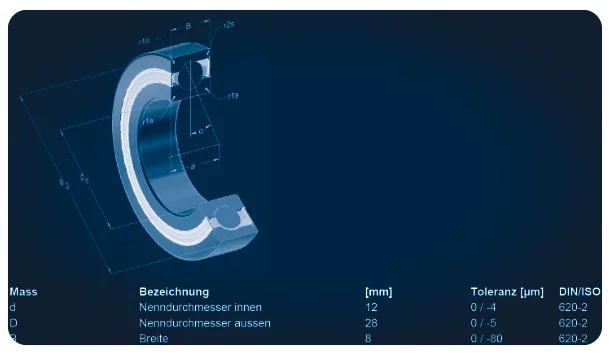

The dimensional, running and shape accuracy of a rolling bearing is determined by the tolerance class. It defines the permissible limits for deviations from nominal diameters, radial run-out, axial run-out or width, depending on the bearing type and the respective area of application.

Measurement & testing in accordance with DIN 620 / ISO 492

For most standard applications, the normal accuracy class according to DIN 620 and ISO 492 is sufficient. In precision applications such as machine tools, spindle systems or measuring devices, higher tolerance classes such as P6, P5, P4 or P2 are used. These classes define tighter limits for radial run-out and form deviation.

The higher the tolerance class, the more precise the running behaviour and the lower the permissible deviations. This has a direct influence on the vibration behaviour, temperature development and service life of the bearing.

where precision moves.