Temperature as a factor influencing bearing geometry

Bearings made of standard steel are designed for operating temperatures up to approximately 120 °C, and up to 150 °C for short periods.

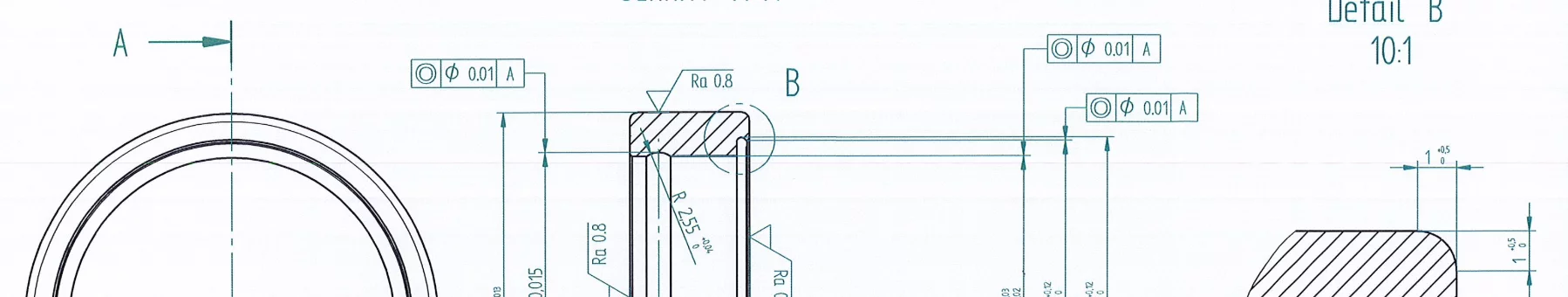

If these values are exceeded, internal tensions and structural changes in the material lead to permanent dimensional changes.

This can affect the bearing clearance, the bearing play and ultimately the function of the entire system.

Stabilisation through targeted heat treatment

Bearings are specifically dimension-stabilised to prevent changes in shape and dimensions at high temperatures.

This involves tempering at higher temperatures, which reduces internal stresses and anticipates structural changes in a controlled manner.

This treatment slightly reduces hardness, but ensures permanent dimensional stability and dimensional accuracy even at sustained high operating temperatures.

Classification and labelling

Dimensionally stable bearings are identified by a suffix consisting of the letter S and a number (e.g. S0, S1, S2).

The number describes the maximum permissible operating temperature at which the bearing retains its geometric stability.

Saurer Ball Bearings defines this classification in accordance with international standards, thereby ensuring that each bearing design is precisely matched to its thermal load.

where precision moves.